- TOP

- Products & Services

- Products

Products

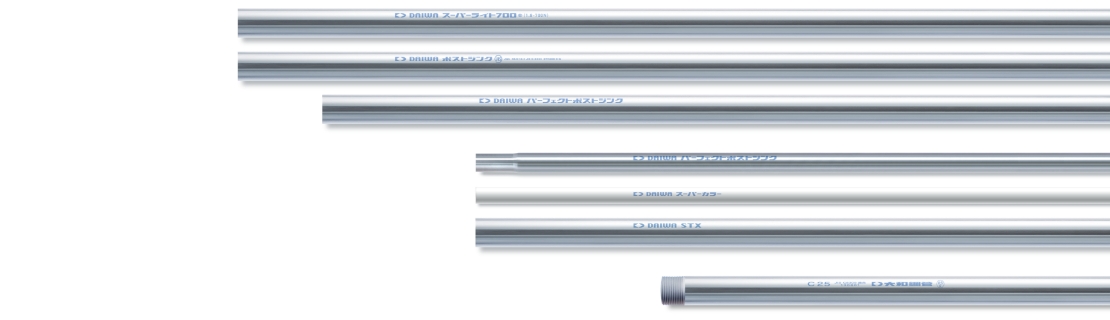

Leading position in strong and lightweight scaffolding tubes! Super Light 700 (SL700)

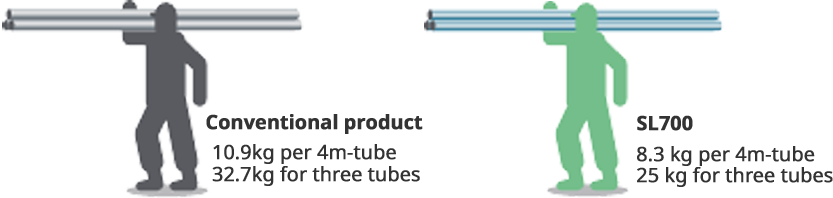

Super Light 700 (SL700) is 25% lighter than its predecessor with the same or even greater strength and can help improve workability and reduce costs.

Twice the strength of conventional materials STX

STX is about twice as strong as a conventional product of the same size. Thus, it can reduce cost by strengthening the structures and reducing the number of components.

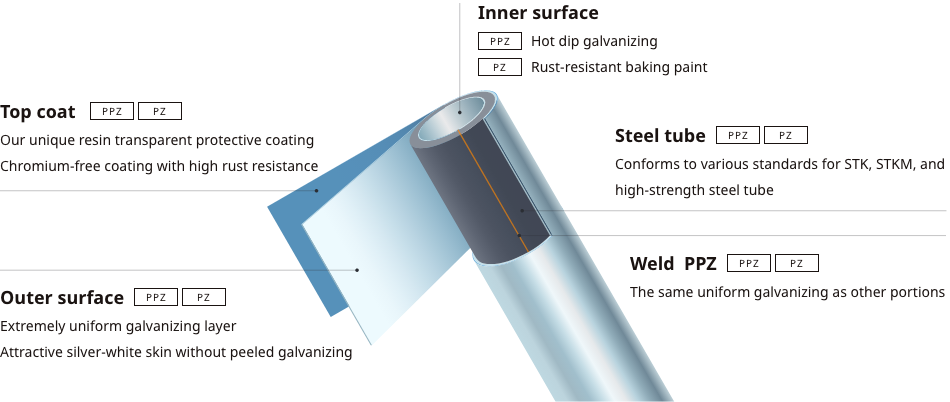

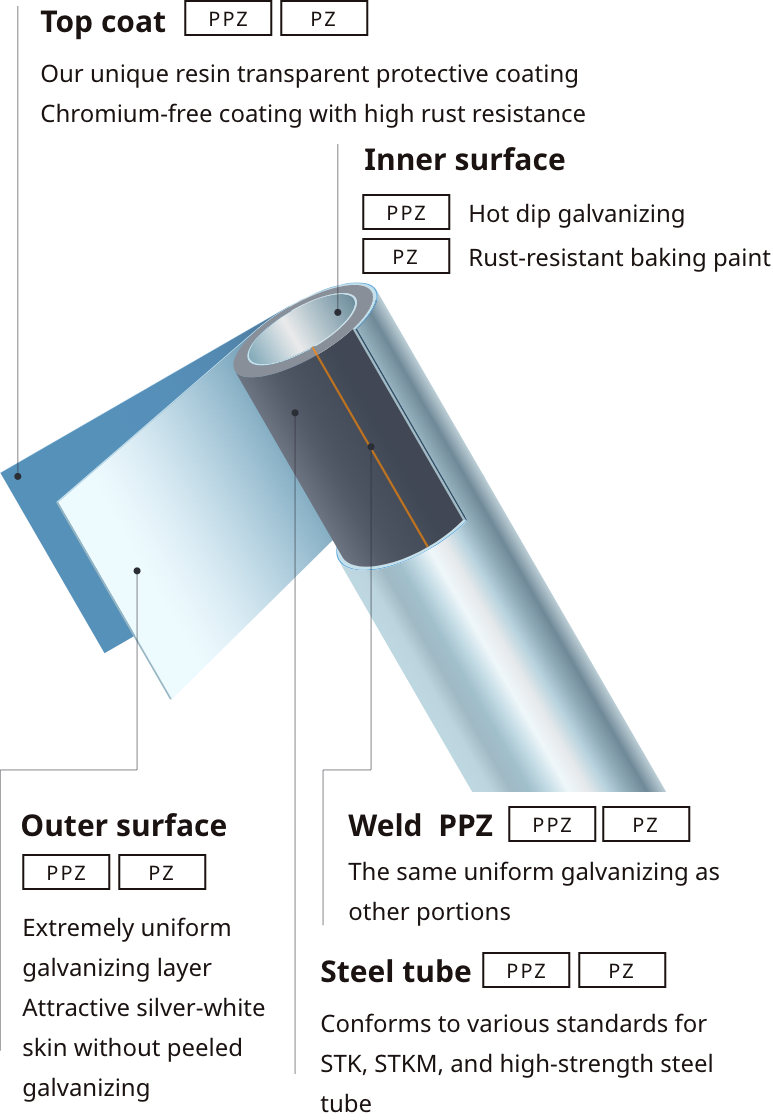

Rust-resistant, beautiful and environment-friendly tubes Perfect Post Zinc(PPZ) Post Zinc(PZ)

Manufactured using our unique “Daiwa Z Process,” a continuous manufacturing process of tube manufacturing and hot dip galvanizing. When compared with other manufacturing methods, this method offers extremely high corrosion resistance and a beautiful appearance, which allows the tube to be used for a wider range of applications.

Specially designed for winding, 3 times more corrosion resistance than conventional products Super Color

Super Color is coated with polyester inside and outside, which helps it withstand the harsh environment of high temperature and humidity.

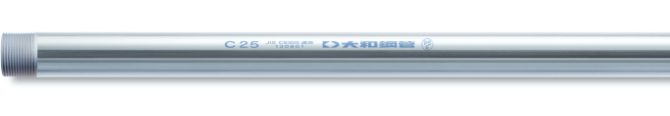

Rigid steel conduits

All the coils which we use to manufacture steel tubes are made by Nippon Steel Corporation. We achieve the high quality required for conduits by using the most advanced steel material and the reliable technology we have cultivated over many years.

JIS Standard products

We manufacture products of outer diameter/thickness dimensions in accordance with Japanese Industrial Standards (JIS).

Product details

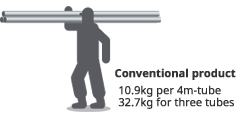

Light, strong, environment-friendly scaffolding tubes Super Light 700 (SL700)

Light, Strong and more efficient

Super Light 700 (SL700) is a lightweight scaffolding tube that perfectly balances the conflicting elements of “light” and “strong” steel tubes. The wall thickness of the steel tube is only 1.8mm. We have succeeded in reducing the weight by 25% and increasing the tensile strength by 40% compared with conventional products. The lightness of the product helps in reducing the workload at the site where the steel tubes are used and decreases the cost of transportation.

Leading position in lightweight scaffold tubes

Super Light 700 (SL700) is being sold since 1996. We take pride in the fact that we have sold 300,000 tons or 60 million units.

Cleared the safety standards of the Ministry of Health, Labour and Welfare

Super Light 700 (SL700) is a scaffolding tube jointly developed with Nippon Steel Corporation. It has been subjected to a 6-row 3-column full-scale load test conducted at the test site for Scaffolding and Construction Equipment Association of Japan, has been recognized by the Ministry of Health, Labor and Welfare as being safe through various strength tests, and has even led to a revision of Article 572 of the Ordinance on Industrial Safety and Health by the Ministry of Health, Labor and Welfare on March 5, 1996.

Flexible and strong steel tubes, twice as strong as conventional products STX

.jpg)

.jpg)

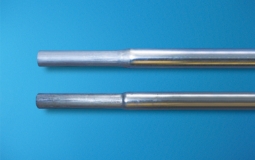

Resistant to natural disasters and flexible in design

STX is a high tensile strength steel tube with twice the strength of conventional materials. Ideal for greenhouses, resistant to natural disasters such as typhoons and snowfalls.

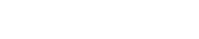

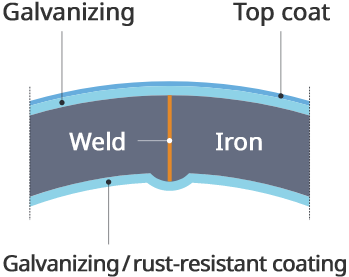

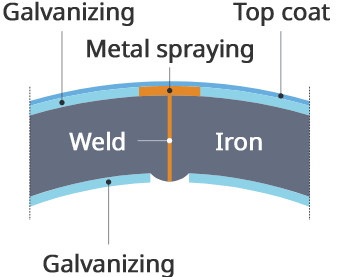

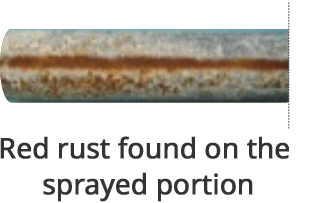

The greenhouse lasts longer due to rust-resistance.

With our unique all-round hot-dip galvanizing, sprayed parts are not prone to rusting. In addition, the unique high corrosion resistant top coat prevents rusting.

“Light,” “Strong,” “Economical”

[Light]

Due to significant strength, the weight can be reduced by reducing the tube size and thickness of the component.

[Strong]

Its high strength allows for increased component strength.

[Economical]

Reduces transport cost due to reduced tube weight and size. The reduction in the surface area of tubes also brings down the painting cost.

Rust-resistant, beautiful and environment-friendly tubes Perfect Post Zinc(PPZ) Post Zinc(PZ)

Comparison of corrosion resistance of PPZ and PZ

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

.png) |

Zinc galvanizing and Daiwa Z Process

Perfect Post Zinc (PPZ) and Post Zinc (PZ) steel tubes are hot dip galvanized steel tubes manufactured by our unique line ~equipment using our “Daiwa~ which continuously performs tube manufacturing and hot dip galvanizing. “Daiwa Z Process” can drastically reduce the thickness of the alloy layer, which impairs corrosion resistance, by shortening the time previously required for immersion in the galvanizing bath from several minutes to several seconds.

Silver-white glow

Pure zinc with 99.995% purity is used for galvanizing, and a top coat (special rustproof transparent resin) is applied after galvanizing. This will ensure that the silver-white glow of Post Zinc is preserved indefinitely.

Excellent workability

The alloy layer of the galvanizing is much thinner than that of the batch hot-dip galvanizing, preventing the plating from cracking or peeling due to bending. High adhesion is achieved by a special high temperature baking paint developed by Daiwa Steel Tube Industries. The paint does not peel off even under severe bending, resulting in excellent workability.

Specially designed for winding, 3 times more corrosion resistance than conventional products Super Color

.jpg)

Polyester coating inside and outside

It has excellent corrosion and weather resistance and can withstand the harsh environment of high temperature and humidity.

Using Z18 equivalent welded galvanized steelsheet

Thickly galvanized on both inside and outside surface, these steel tubes are highly resistant to corrosion and effective in preventing rust.

Rigid Steel Conduits

.jpg)

All of the coils we use to manufacture steel tubes are made by Nippon Steel Corporation. We achieve the high quality required for conduits by using the most advanced steel material and the reliable technology we have cultivated through tube manufacturing and hot-dip galvanizing over many years.

Thick steel conduits

Thick steel tubes are threaded at both ends, conforming to the JIS C8305-2019 Standard. Hot-dip galvanizing is applied on inside and outside surfaces to prevent corrosion.. (Zinc adhesion: 300 g/m2 or more)

Thin steel conduit

Thin tubes are threaded at both ends, conforming to the JIS C8305-2019 < Steel Conduit > Standard. Hot-dip galvanizing is applied to external surfaces, and rust-proof paint is applied to internal surfaces. The outer surface is hot-dip galvanized over the entire circumference, including the electric welded parts of the tube, similar to thick steel conduits.

Threadless conduit

Threadless conduit, conforming to the JIS C8305-2019 < Steel Conduit > Standard. Hot-dip galvanizing is applied to external surfaces and rust-proof paint is applied to internal surfaces, similar to thin steel conduits. Thin and lightweight tube with excellent workability.

Product specifications

Anti-corrosion treatment

| Product name | Tube outer surface | Tube inner surface |

|---|---|---|

| Perfect Post Zinc (PPZ) | Hot dip galvanizing + top coat (chrome-free) | Galvanizing |

| Post Zinc (PZ) | Hot dip galvanizing + top coat (chrome-free) | Anti-corrosion coating |

| Black tube | – | – |

Standards

Carbon steel tube for general structure (JIS G 3444)

| Type symbol | Tension test | Bending test | Flattening test | Main applications | |||

|---|---|---|---|---|---|---|---|

| Tensile strength N/mm2 | Yield point or yield strength N/mm2 | Growth % | Bending angle | Inner radius (D is the outer diameter of the tube) |

Distance between flat plates (H) (D is the outer diameter of the tube) |

||

| No. 11 test piece No. 12 test piece |

|||||||

| STK290 | 290 or more | – | 30 or more | 90° | 6D | 2/3D | Agricultural and structural use |

| STK400 | 400 or more | 235 or more | 23 or more | 90° | 6D | 2/3D | Agricultural and structural use |

| STK500 | 500 or more | 355 or more | 15 or more | 90° | 6D | 7/8D | Scaffolding tube, temporary component |

| STK290 | Tension test | ・Tensile strength N/mm2: 290 or higher ・Yield point or yield strength N/mm2: - ・Growth %/ No. 11 test piece No. 12 test piece: 30 or more |

|---|---|---|

| Bending test | ・Bending angle: 90° ・Inner radius (D is the outer diameter of the tube): 6D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 2/3D | |

| Main applications | Agricultural and structural use | |

| STK400 | Tension test | ・Tensile strength N/mm2: 400 or higher ・Yield point or yield strength N/mm2: 235 or more ・Growth %/ No. 11 test piece No. 12 test piece: 23 or more |

| Bending test | ・Bending angle: 90° ・Inner radius (D is the outer diameter of the tube): 6D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 2/3D | |

| Main applications | Agricultural and structural use | |

| STK500 | Tension test | ・Tensile strength N/mm2: 500 or higher ・Yield point or yield strength N/mm2: 355 or more ・Growth %/ No. 11 test piece, No. 12 test piece: 15 or more |

| Bending test | ・Bending angle: 90° ・Inner radius (D is the outer diameter of the tube): 6D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 7/8D | |

| Main applications | Scaffolding tube, temporary component |

Carbon steel tube for mechanical structure (JIS G 3445)

| Type / symbol | Tension test | Bending test | Flattening test | Main applications | |||

|---|---|---|---|---|---|---|---|

| Tensile strength N/mm2 | Yield point or yield strength N/mm2 | Growth % | Bending angle | Inner radius (D is the outer diameter of the tube) |

Distance between flat plates (H) (D is the outer diameter of the tube) |

||

| No. 11 test piece No. 12 test piece |

|||||||

| Class 11 A / STKM11A | 290 or more | – | 35 or more | 180° | 4D | 1/2D | Conveyors, tents |

| Class 12 A / STKM12A | 340 or more | 175 or more | 35 or more | 90° | 6D | 2/3D | |

| Class 12 B / STKM12B | 390 or more | 275 or more | 25 or more | 90° | 6D | 2/3D | |

| Class 11 A / STKM11A | Tension test | ・Tensile strength N/mm2: 290 or higher ・Yield point or yield strength N/mm2: - ・Growth %/ No. 11 test piece, No. 12 test piece: 35 or more |

|---|---|---|

| Bending test | ・Bending angle: 180° ・Inner radius (D is the outer diameter of the tube): 4D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 1/2D | |

| Main applications | Conveyors, tents | |

| Class 12 A / STKM12A | Tension test | ・Tensile strength N/mm2: 340 or higher ・Yield point or yield strength N/mm2: 175 or more ・Growth %/ No. 11 test piece, No. 12 test piece: 35 or more |

| Bending test | ・Bending angle: 90° ・Inner radius (D is the outer diameter of the tube): 6D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 2/3D | |

| Main applications | Conveyors, tents | |

| Class 12 B / STKM12B | Tension test | ・Tensile strength N/mm2: 390 or higher ・Yield point or yield strength N/mm2: 275 or more ・Growth %/ No. 11 test piece, No. 12 test piece: 25 or more |

| Bending test | ・Bending angle: 90° ・Inner radius (D is the outer diameter of the tube): 6D |

|

| Flattening test | ・Distance between flat plates (H) (D is the outer diameter of the tube): 2/3D | |

| Main applications | Conveyors, tents |

Square steel tube for general structure (JIS G 3466)

| Type symbol | Tensile strength N/mm2 | Yield point or yield strength N/mm2 | Growth % | Main applications |

|---|---|---|---|---|

| No. 5 test piece | ||||

| STKR400 | 400 or more | 245 or more | 23 or more | Flap angle Foundation shoring |

| STKR490 | 490 or more | 325 or more | 23 or more |

| STKR400 | ・Tensile strength N/mm2: 400 or higher ・Yield point or yield strength N/mm2: 245 or more ・Growth %/ No. 5 test piece: 23 or more |

|---|---|

| Main applications | Flap angle, for agriculture |

| STKR490 | ・Tensile strength N/mm2: 490 or higher ・Yield point or yield strength N/mm2: 325 or more ・Growth %/ No. 5 test piece: 23 or more |

| Main applications | Flap angle Foundation shoring |

Steel conduit (JIS C 8305) (JIS C 8380)

| Type | Specifications | Main applications |

|---|---|---|

| Thick steel conduits | Inner and outer surface galvanizing, both ends threaded | Conduit |

| Thin steel line | Outer surface galvanizing, both ends threaded | |

| Threadless conduit | Outer surface galvanizing, threadless | |

| Polyethylene-lined conduit | Inner and outer surface polyethylene resin coating, both ends threaded |

| Thick steel conduits | Specifications: Inner and outer surface galvanizing, both ends threaded |

|---|---|

| Main applications | Conduit |

| Thin steel line | Specifications: Outer surface galvanizing, both ends threaded |

| Main applications | Conduit |

| Threadless conduit | Specifications: Outer surface galvanizing, threadless |

| Main applications | Conduit |

| Polyethylene-lined conduit | Specifications: Inner and outer surface polyethylene resin coating, both ends threaded |

| Main applications | Conduit |

High-tensile steel tube

| Applications | Product name | Tensile strength N/mm2 | Yield point or yield strength N/mm2 | Growth % | Yield ratio % | Steel tube thickness mm | Remarks |

|---|---|---|---|---|---|---|---|

| Lightweight scaffolding tubes | Super Light 700 (SL700) | 700 or more | 570 or more | 10 or more | – | 1.8 | Conforms to the Ordinance on Industrial Safety and Health |

| For building structures | 700N class structural high-tensile carbon steel tube | 700 or more | 520-760 | 10 or more | 90 or less | 2.0 or more | Minister of Land, Infrastructure, Transport and Tourism Certification approved (No.MSTL-0197) |

| For general structures (agricultural, tents) | STX | 700 or more | 570 or more | 10 or more | – | 2.0 or more | – |

| 780 or more | – | – | – | 1.2 / 1.6 |

| Lightweight scaffolding tubes Super Light 700 (SL700) |

・Tensile strength N/mm2: 700 or higher ・Yield point or yield strength N/mm2: 570 or more ・Growth %: 10 or more ・Yield ratio %: - ・Steel tube thickness mm: 1.8 |

|---|---|

| Remarks | Conforms to the Ordinance on Industrial Safety and Health |

| For building structures 700N class structural / high-tensile carbon steel tube |

・Tensile strength N/mm2: 700 or higher ・Yield point or yield strength N/mm2: 520-760 ・Growth %: 10 or more ・Yield ratio %: 90 or less ・Steel tube thickness mm: 2.0 or more |

| Remarks | Minister of Land, Infrastructure, Transport and Tourism Certification approved No. MSTL-0197 |

| For general structures (agricultural, tents) STX |

・Tensile strength N/mm2: 700 or higher ・Yield point or yield strength N/mm2: 570 or more ・Growth %: 10 or more ・Yield ratio %: - ・Steel tube thickness mm: 2.0 or more ・Tensile strength N/mm2: 780 or higher ・Yield point or yield strength N/mm2: - ・Growth %: - ・Yield ratio %: - ・Steel tube thickness mm: 1.2 / 1.6 |

Certifications

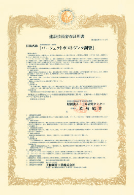

Perfect Post Zinc (PPZ)

Public Works Research Center

Construction Technology Examination Certification proves corrosion resistance equivalent to hot dip galvanizing

700N class structural / high-tensile carbon steel tube (STX700) (STXR700)

Minister of Land, Infrastructure, Transport and Tourism

Obtained certification as a designated building materialProcessing options

Swage

Pitch mark

Cutting

Surface painting

Pinning

Drilling

Stencil

Tube end painting